|

Over the course of the next 40 thousandths of a second

you, Mr. or Ms. Molecule, will be beaten through 18 stages of

compression, singed in a furnace heated to nearly 3,000 degrees

Fahrenheit, expanded through a turbine and pushed out the back with

a wicked headache and the bitter knowledge as the aircraft screams

on that your ugly ordeal has been merely for the sake of getting

Aunt Mildred to Phoenix for a much needed rest.

That’s

basically what happens every day in the skies above as thousands of

Pratt engines power aircraft from place to place while the

passengers and crew inside those aircraft experience only the steady

and reassuring thrum that results from Pratt’s precision

manufacturing.

The principle

of jet propulsion has been demonstrated by anyone who has blown up a

balloon for a child and accidentally let go before tying it closed.

The air stored up inside the balloon accelerates as it rushes to

escape through the narrowest part of the balloon’s neck. This

acceleration, or change in the speed of air, combines with the

weight of the air itself to produce thrust. It is the thrust that

sends the renegade balloon zipping madly about the room.

The original

turbojet engine, which debuted in scheduled commercial service in

1952, accomplished this same trick on a breathtaking scale and with

pinpoint control. The progress of jet engine technology in the past

four decades has been to increase the amount of air going into the

engine, and change the speed of that air with ever greater

efficiency. All the examples in the article are drawn from the

mightiest family of engines ever to fly, the Pratt & Whitney

4000s. | |

|

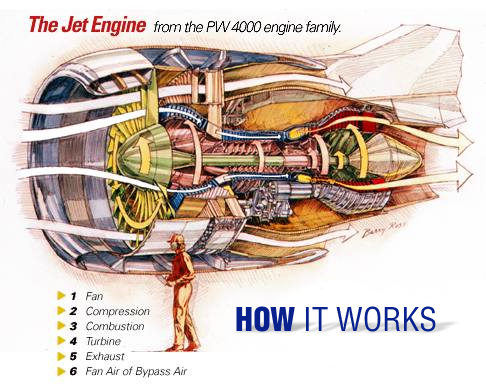

| 1. Fan |

The propulsion process

begins with the huge, 9-foot-diameter fan at the front of the

engine, spinning 2,800 times a minute at takeoff speed. That fan

sucks in air at the rate of 2,600 pounds per second, or enough to

vacuum out the air from a 4-bedroom house in less than half a

second. |

| 2. Compression |

As

the air leaves the fan it is now separated into two streams. The

smaller stream, about 15 percent of the total volume of air, is

called primary or core air and enters the first of two compressors

that are spinning in the same direction as the fan itself. As the

primary air passes through each stage of the two compressors, both

its temperature and pressure rise. |

| 3.

Combustion |

When compression is

complete, the air, now 30 times higher in pressure and 1,100 degrees

hotter, is forced through a furnace or combustor. In the combustion

chamber, fuel is added and burnt. The air’s temperature soars even

higher, and the air is finally ready to do the two jobs for which it

has been so hastily prepared. |

| 4. Turbine |

The first job is to blast through the blades of two

turbines, sending them whirling just like the wind spinning the arms

of a windmill. The whirling turbines turn the shafts that drive both

compressors and the fan at the front of the engine. This process, in

which the engine extracts energy from the air it has just captured,

is what allows modern jets to operate with such high fuel

efficiency. |

| 5. Exhaust |

The second job is to

push the airplane. After passing through the turbines, the hot air

is forced through the exhaust opening at the back of the engine. The

narrowing walls of the exhaust force the air to accelerate and, just

as with the balloon, the weight of the air combined with its

acceleration drives the engine, and the airplane attached to it,

forward. |

6. Fan Air or

Bypass Air |

The larger air

stream exiting the fan, representing 85 percent of the total, is

called fan air or bypass air, because it bypasses this entire

process.

The engine

itself is shrouded in a metal casing called the nacelle, shaped

roughly like a sideways ice cream cone with the bottom cut off.

Bypass air is forced through the ever narrower space between the

nacelle wall and the engine, picking up speed along the way.

Because of its

huge volume, bypass air needs only to accelerate a small amount to

produce an enormous kick of thrust. In the PW4084 engine, bypass air

accounts for 90 percent of the thrust, and has the added benefits of

keeping the engine cooler, quieter and more fuel efficient.

| |